Featured Project Return to Projects List

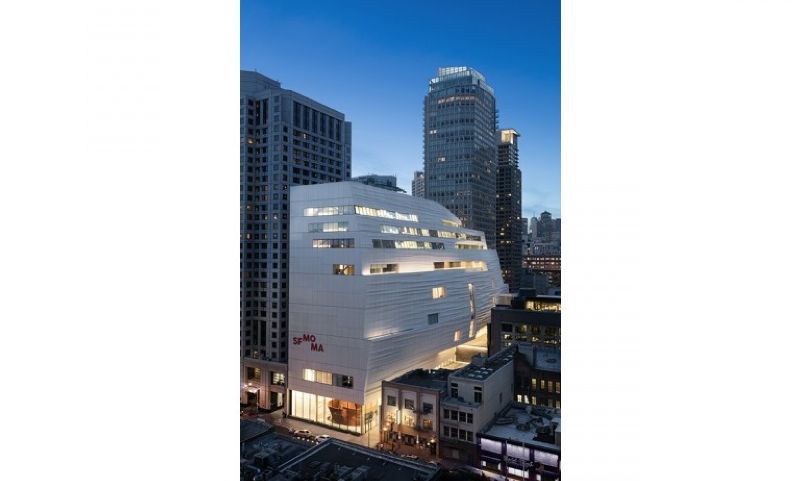

San Francisco Museum of Modern Art: Expansion

Project Information

- Project Location:

- San Francisco, CA

- Status:

- Completed

- Structure Type:

- Museum

References

- Owner:

- SFMOMA

- Architect:

- EHDD Architecture/Snøhetta

Scope Of Work

The new Snøhetta-designed SFMOMA Expansion amends the Mario Botta-design building that first debuted in 1995. The project aimed to create a more welcoming SFMOMA, utilizing a multitude of new entrances that engage with the surrounding South of Market (SoMa) neighborhood. This was achieved by elevating the building mass above street level to create a network of circulation spaces, terraces, and outdoor sculpture gardens. In total, the expansion nearly triples the gallery space for the museum’s growing collection.

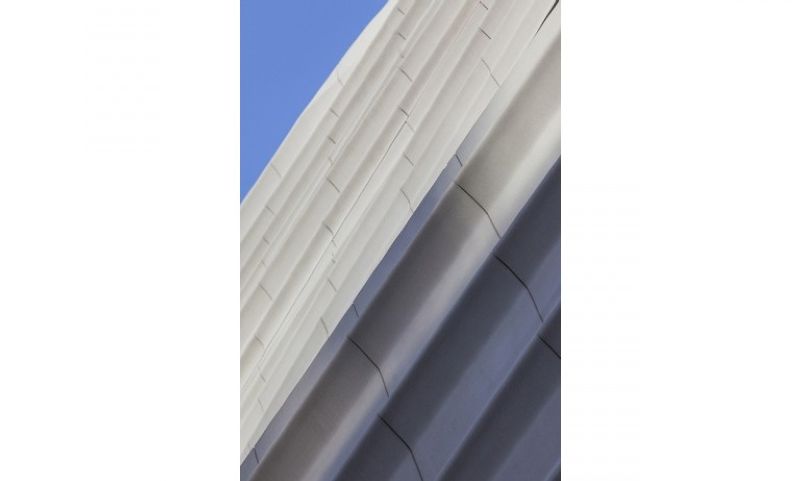

A primary feature of the 10-story Snøhetta expansion is the rippling horizontal bands of the facade that were inspired by the fog and waters of the San Francisco Bay. The feature wall – the largest architectural application of fiberglass reinforced plastic (FRP) in the United States – consists of a composite assembly of an opaque FRP rain-screen panel in front of an insulated unitized backup system.

The project was designed under a design-assist contract with the architect, meaning the design underwent many changes that required continual updates to cost estimates and material take-offs to validate targets were met. The architect initially provided standard architectural drawings and a BIM model. The initial information provided was based on design development and would knowingly change multiple times throughout the design lifespan of the project. The design team worked collaboratively to narrow in on a design solution that achieved architectural desire within budgetary constraints and material limitations.

The make-up of the enclosure was a juxtaposition of two key layers: 1) an outer rippled surface made of contoured fiberglass reinforced polymer (FRP) fabricated by Kreysler & Associates, and 2) an insulated opaque performance barrier with interlocking curtainwall technology and insulation. The outer ripple surface required each panel to be a unique geometry, thus requiring intensive CNC milling technology of unique molds for each of the 700+ panels out of polystyrene blocks. The inner performance curtainwall maximized off-site, shop-controlled assembly to maximize quality control of key features. Following fabrication of the FRP panels, they were transported to the curtainwall assembly shop where the two systems were mated before delivery to site. Both shops were within 40 miles of the project site.

Other noteworthy wall type descriptions include:

Wall type one occurs at the Howard Street Gallery. The desire for maximum transparency led the design team to use large insulated glass units. The glass lites are 8’-0" x 19’-1” with shorter 8’-0" x 6’-7” lites stacked on top. Each lite is backed vertically by a 2.5” x 6” milled AESS vertical mullion with a blackened finish. The wall’s design includes several removable mullions to accommodate the delivery of large sculptural pieces, including the current Serra sculptures that occupy the lobby space.

Wall type two also relies on large glass to create a vertical slot through the FRP facade to create views down Natoma Street. This glazed band includes two planes, comprised of nine lites to horizontally span the aperture. This requires 2 5/8” thick insulated glass units that are each 14’-6" x 7’-6" and weigh 3,000 pounds.

Wall type six-A is the aforementioned unitized FRP rain-screen system. The system uses several design features to accommodate the varying angles of the opaque insulated units, including top of slab anchors, circular lifting lugs to permit rotation at various slopes and folded transition units in areas of strong curvature.

Wall type six-B is the flat, unitized aluminum spandrel panels that wrap the non-FRP rain-screen elevations. The insulated spandrel units are 5’-4” x 16’-0” and use intermediate horizontal mullions to introduce horizontal breaks in the regular pattern. Mineral wool insulation, 5 1/2" thick, was integrated into the curtainwall unit to provide a system that meets the strict thermal transmission requirements of the project.

The SFMOMA enclosure is the result of a collaborative union between architect Snøhetta, leading FRP manufacturer Kreysler & Associates of American Canyon, California, and Enclos, one of the largest facade contractors in the United States.

You may experience a virtual tour of the manufacturing processes and installation sequences that brought this visionary facade to life here.

A detailed case study of the FRP delivery process is available here courtesy of Composites World.