Featured Project Return to Projects List

Montgomery County Public Schools Fats, Oils & Grease Compliance Design-Build

Project Information

- Project Location:

- Montgomery County, MD

- Approx Contract:

- $5,683,211

- Status:

- Completed - Aug 2014

- Structure Type:

- School / College / University

References

- Owner:

- MCPS

- Architect:

- N/A

- General Contractor:

- Shapiro & Duncan, Inc.

Scope Of Work

CASE STUDY

Challenge

Abatement of Fats, Oils and Grease - collectively known as FOG - in commercial kitchen renovation projects is becoming increasingly problematic for mechanical engineering contractors. Not only do contractors have to deal with complex codes and ordinances at the national and local levels, but they must also maintain an effective flow of communication with the building owner and the local water and sewer authority.

As a result of the stringent FOG regulations that were enacted in 2006 by the U.S. Environmental Protection Agency (EPA), food service establishments (FSEs) all over the country but specific to our territory the Washington Suburban Sanitary Commission (WSSC) jurisdictions of Montgomery County, MD and Prince Georges County, MD have found themselves creating new processes and procedures to manage compliance. The WSSC defines a FSE as "any restaurant, cafeteria, hotel kitchen, church kitchen, hospital cafeteria, bar and other commercial or industrial operation that discharges wastewater that contains FOG." Local school system facilities fall under this definition.

School systems such as the Montgomery County Public Schools (MCPS) are no strangers to coordinating construction projects commencing from a jurisdictional violation or to upgrade systems to remain in compliance. But when MCPS was cited by WSSC for almost 150 FOG violations early in 2012, this created an unprecedented administrative and logistical situation that MCPS had to tackle and resolve.

The MCPS FOG abatement system project was awarded to Shapiro & Duncan, following a best value design-build selection process, in April of 2012. MCPS was seeking a revolutionary path to resolve the problem at hand - they wanted a contractor to design and build the work, administer the contract and coordinate directly with WSSC. The contract covered 147 school sites (out of a total of 160 schools in the system) that were cited by WSSC for violations of FOG regulations. MCPS was overwhelmed with the extent of these FOG citations, which included multiple violations at each site.

The project required an extra level of customer service as our project team was dealing with so many schools, as well as an extra level of technical and regulatory competency on our part because of the intricacies of FOG compliance. That's why the design-build method was chosen to meet the unique aspects of this project and relieve the school system of the burden of administering this complex contract.

Operationally, the biggest challenge was scheduling work to ensure that it did not interfere with ongoing cafeteria operations and other school operations. This required close coordination with school principals and cafeteria managers.

In addition, the field conditions for construction (drainage and existing plumbing infrastructure) varied widely across the 147 sites included in this project scope of work. Approximately two-thirds of the school buildings in MCPS are elementary schools and one-third are middle schools and high schools. There are thousands of drains in kitchens, trash rooms and concession stands that needed to be brought into compliance with WSSC's FOG standards.

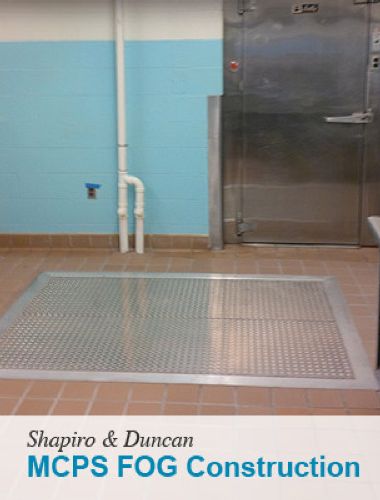

At elementary schools, where most of the food served in school cafeterias is prepared at the central kitchen and then reheated, we had to install grease abatement systems for the first time. Previously, there had been no grease interceptors at MCPS elementary schools; wastewater effluent was diverted directly into the sanitary sewer system.

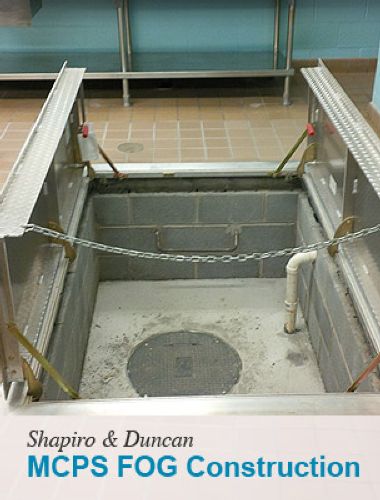

At middle schools and high schools, while the bulk of the food is prepared at a central facility, the volume is higher and some food preparation is done in the school kitchen. For these reasons, floor drains must be connected to a grease interceptor. This means the renovation work at middle schools and high schools involved cutting up the floor.

Trash rooms, which often have a trash compactor, also must be connected to a school's grease abatement system. This is because milk and greasy fluids can leak from the trash compactor into the floor drain in the trash room. Trash room floor drains, therefore, do not receive a grease abatement exemption from the WSSC. As a result, we had to cut up trash room floors at MCPS project sites to make sure the floor drains flowed through a grease interceptor tank.

Solution

Within two weeks of the contract awarded, our project team had established a project implementation system that could be replicated across all 147 school sites. This system comprehensively covered:

- First for project accounting we created 147 individual sub jobs (One for each school site).

- Then we created a detailed CPM master schedule to ensure completion at all sites by mid-August 2014.

- We conducted field surveys at typical sites to develop a control estimate for each site.

- We then reviewed all of the project requirements and constraints with our foremen, trade subcontractors and our in-house engineering and computer-assisted design (CAD) staff. Trade subcontractors, in particular, were carefully screened for their ability to handle a project of this size and scope. Agility was key.

- Tailoring our billing system to suit the needs of MCPS, which included creating custom reports comparing the current monthly time and material costs against the control estimate and construction schedule.

We also put in place a quality control program to ensure construction would meet or exceed our own internal quality standards as well as those required by MCPS. We found the best way to manage the quality control process was to develop standard techniques and forms, and then tailor them over the course of the next two years to individually meet the expectations of each school's scope of work.

On-site collaboration and coordination was the final element of our solution. From initial engineering site surveys to day-to-day communication between our design team and subcontractors on the jobsite, we had to make sure that we had the right manpower in the right place at every MCPS school.

Result

With our framework in place, we moved to the construction phase. This proved to be a sequential symphony of pre-construction site surveys, design/engineering, drawing submission to WSSC to obtain permits, coordination of the work schedule at each school, implementation of construction, demobilization and close out.

Streamlined communication and coordination with the school system and WSSC was one of the keys to the success of our design-build approach. Our team was able to work smoothly with the water authority as well as provide a high level of coordination and customer service with MCPS.

The bottom line for Shapiro & Duncan is that this project came in on time and under budget. We took on the MCPS's FOG problem and made it go away. There is no doubt that our design-build approach was the most efficient way to deal with the myriad of problems our project team faced across 147 job sites. In every way, this project achieved the highest level of success for all stakeholders.