Featured Project Return to Projects List

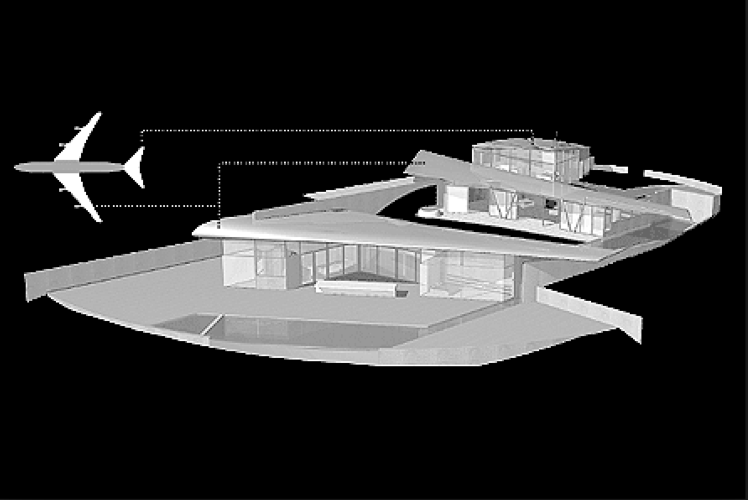

747 Wing House

Project Information

- Project Location:

- Malibu, CA

- Approx Contract:

- $150,000

- Status:

- Completed - Aug 2010

- Structure Type:

- House

References

- Owner:

- Francie Rehwald

- Architect:

- David Hertz

- General Contractor:

- Rod Spector & Co

- Client:

-

David

Hertz

-

President

(310) 829-9932David Hertz Architects

Scope Of Work

http://davidhertzfaia.com/747-wing-house/

Architect David Hertz has designed a home by recycling the 4.5 million parts of this Boeing 747. This project is on a 55-acre property in the remote hills of Malibu. The site was previously owned and developed by the eccentric designer Tony Duquette.

Allied Roofing and Waterproofing, Inc. was contacted by Architect David Hertz to assist in the roofing design construct phase of this project. We consulted with John Segin of Versico Roofing Products, a product that Architect David Hertz had previously implemented into the rooftop studio of Syndesis located in Santa Monica, California. We designed a Class A Fire Rated roofing system by installing a three step process of PolyGlass Self-Adhesive membranes applied directly to the existing aluminum, composite, and wood substrates of the recycled 747 wings. We were able to achieve a Class A Fire Rating with the PolyGlass Self-Adhesive membranes without the use of fasteners or fire retardant sheet barriers. The use of fasteners for the roofing system was not an option as the fasteners would telegraph through the final layer of Versico TPO roofing membrane and be visible from the different viewpoints of the 747 wing house. The PolyGlass Self-Adhesive membranes have a granular mineral surface, which provides a great point of adhesion substrate for the final layer of Versico TPO roofing membrane, which was to be fully adhered to the PolyGlass membranes. Architect David Hertz wanted a roofing membrane to complement the original aluminum and composite substrate of the recycled 747 wings. Our team provided Architect David Hertz with the Versico TPO (Thermoplastic Polyefin) “Grey” roofing membrane as the perfect product for the job. The Versico TPO roofing membrane was fully adhered to the PolyGlass membranes with water based low VOC bonding adhesive thus eliminating the need for unsightly fasteners.

We worked with Architect David Hertz in providing a suitable layout of the Versico TPO roofing membrane as to replicate the metal panel simulation of the original aluminum and composite substrate of the recycled 747 wings. The real challenge was finishing the roofing membrane along the radial and knife-edges of the 747 wings. In working with our sheet metal fabricator, we were able to design a TPO Clad metal as manufactured by Versico Roofing Products in which the “Grey” TPO membrane was fabricated fused to the aluminum clad metal. The TPO Clad metal was then custom fit to replicate the shapes of the radial and knife-edges of the 747 wings. Our technicians then welded custom Versico TPO non-reinforced membrane between the TPO clad metal and original installation roof areas. The field membrane of the Versico TPO was secured with a 1″ wide aluminum termination metal beneath the custom clad metal perimeter edging thus preventing wind uplift as the 747 wing project sits at the top of a canyon above Point Mugu. The Versico TPO “Grey” membrane was not as reflective as the white membrane but did provide a Solar 747 Boeing jet. Reflectance of 46% after the initial installation.

May 2010, 4myroof a subsidiary of Allied Roofing and Waterproofing, Inc. designed a Class A Fire Rated roofing system by installing a three step process of PolyGlass Self-Adhesive membranes applied directly to the existing aluminum, composite, and wood substrates of the recycled 747 wings. We were able to achieve a Class A Fire Rating with the PolyGlass Self-Adhesive membranes without the use of fasteners or fire retardant sheet barriers. The use of fasteners for the roofing system was not an option as the fasteners would telegraph through the final layer of Versico TPO roofing membrane and be visible from the different viewpoints of the 747 wing house. The PolyGlass Self-Adhesive membranes have a granular mineral surface which provides a great point of adhesion substrate for the final layer of Versico TPO roofing membrane which was to be fully adhered to the PolyGlass membranes. Architect David Hertz wanted a roofing membrane to complement the original aluminum and composite substrate of the recycled 747 wings. Our team provided Architect David Hertz with the Versico TPO (Thermoplastic Polyefin) “Grey” roofing membrane as the perfect product for the job. The Versico TPO roofing membrane was fully adhered to the PolyGlass membranes with a water based low VOC bonding adhesive thus eliminating the need for unsightly fasteners.

All in all, the Architect David Hertz and owner Francine Rehwald were extremely pleased with the care and consideration that the 4myroof team took into implementing and installing the first ever roof of it’s kind to the recycled wings of a 747 Boeing jet.